Mining operations rely on efficient pipeline transport systems for handling slurry and tailings—the waste materials produced from ore processing. These materials are highly abrasive, containing a mixture of fine rock particles, water, and chemicals. If not properly managed, they can cause severe pipeline blockages, increased wear and tear, and costly maintenance issues.

One of the biggest challenges in mining slurry transport is air entrapment, which leads to flow restrictions, pressure fluctuations, and pipeline surges. This is where Vent-O-Mat air valves come into play—providing a specialized solution to control air release, pressure surges, and optimize flow efficiency in extreme mining conditions.

Challenges in Slurry Handling in Mining Pipelines

Unlike water or sewage pipelines, slurry pipelines operate under high-stress conditions due to the abrasive nature of materials. Some of the most common challenges include:

1. Slurry Abrasion and Clogging

- Fine and coarse particles in the slurry create constant wear on pipelines and valves.

- Blockages occur when air pockets mix with solid particles, reducing pipeline efficiency.

2. Pressure Surges and Water Hammer Effect

- Air trapped in the system can cause sudden pressure fluctuations, leading to pipeline bursts.

- A sudden stoppage of slurry flow (such as during power failure) can create a backflow surge, damaging the infrastructure.

3. Gas Accumulation in Tailings Pipelines

- Gases naturally dissolved in slurry can accumulate over time, creating airlocks in the system.

- These air pockets reduce pumping efficiency, increasing operational costs.

Without high-performance air valves, mining companies face frequent downtime, high maintenance costs, and potential environmental hazards due to pipeline failures.

Also Read: Mastering Flow Control: Unveiling Vent-O-Mat NCV Air Valves

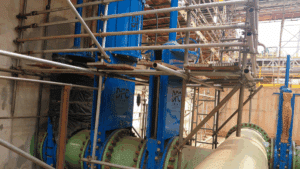

Why Vent-O-Mat Air Valves Are Ideal for Mining Pipelines

Vent-O-Mat air valves are specifically designed to handle the extreme conditions of mining slurry pipelines, offering long-term reliability and operational efficiency.

1. Heavy-Duty Performance in Harsh Environments

- Built for durability – Engineered with high-grade ductile iron, resistant to corrosion and wear.

- Handles abrasive slurry – Designed to operate under constant exposure to solid particles.

2. Advanced Surge and Pressure Control

- Prevents water hammer – Automatically releases trapped air before pressure builds up.

- Manages gas accumulation – Reduces airlocks in pipelines for uninterrupted flow.

3. Energy and Cost Efficiency

- Improves pump efficiency – Reduces air-induced resistance, optimizing energy use.

- Minimizes maintenance – Prolongs pipeline lifespan, saving on costly repairs.

4. Designed for Tailings Management Systems

- Vent-O-Mat’s RGXII and RPS Lightweight Valves are ideal for tailings disposal, preventing pipeline blockages and reducing environmental risks.

🔗 Learn more about Vent-O-Mat’s mining solutions: Mining & Mineral Processing Air Valves

FAQ: Common Questions About Mining Air Valves

1. How do air valves improve slurry transportation efficiency?

By eliminating airlocks and pressure surges, air valves reduce energy losses, allowing pumps to operate at maximum efficiency.

2. Can Vent-O-Mat valves handle highly abrasive materials?

Yes! Vent-O-Mat valves are made from high-strength ductile iron, built to withstand continuous exposure to abrasive slurry.

3. Do these valves work in deep mining operations?

Absolutely. Vent-O-Mat valves are engineered for high-pressure environments, making them ideal for deep underground mining operations.

Mining operations depend on reliable slurry transport systems for continuous production. By integrating Vent-O-Mat air valves, companies can reduce operational risks, lower maintenance costs, and improve pipeline efficiency.

Looking for the best air valves for mining?

Get in touch with us today!