Acid sampling lines sit at the centre of plant safety and compliance. Power generation teams handle aggressive chemicals under pressure and heat. A leak triggers downtime, exposure risk, and clean-up costs. Saunders diaphragm valves support controlled sampling and chemical dosing with a design intended for corrosive and abrasive service, including full bore options developed for 100 percent leak-tight closure.

Why acid sampling needs specialised valve solutions

Acid sampling supports accurate control in dosing and water treatment. Acid service places constant stress on metal surfaces and sealing interfaces. Temperature swings and pressure changes add mechanical load. If shut-off performance drops, seepage starts. Seepage can escalate into a safety incident.

Sampling points often sit in high-activity operational zones. Operators cycle valves during routine checks. Maintenance teams isolate sections during planned work. Each cycle adds wear. If a valve takes too long to service, teams delay intervention. Delays increase risk and extend shutdown windows.

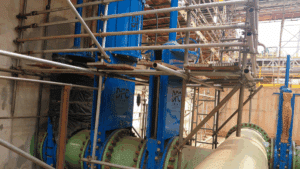

Where Saunders diaphragm valves fit in power generation environments

Power stations and utility contractors manage several chemical systems across plant operations. Saunders diaphragm valves fit high-risk points where leak prevention and corrosion resistance matter.

Acid sampling lines

Sampling lines need stable isolation at the sampling point. Leak-tight shut-off reduces exposure during sampling and maintenance.

De-mineralised water systems

De-min circuits demand contamination control and consistent flow behaviour. These systems form part of broader water quality management.

Boiler feedwater treatment

Feedwater treatment uses conditioning chemicals for corrosion control. Valve selection must match chemical compatibility and duty cycle demands.

Cooling water chemical injection points

Cooling circuits often require controlled dosing. Valve performance affects injection stability and maintenance workload.

FGD and wastewater treatment environments

FGD and WWTP duties involve aggressive media and dosing regimes. Corrosion resistance and shut-off performance matter at isolation and sampling points.

How diaphragm valves support safer acid sampling

Diaphragm valves suit chemical handling because the diaphragm forms the primary sealing element. This supports clean isolation between the process media and the operating mechanism. It also suits frequent cycling where sampling routines demand regular isolation.

On Saunders A Type valves, DFC highlights a pocketless design, low maintenance operation, and a field replaceable heavy-duty diaphragm. The Type-A diaphragm is generally very well suited for control due to its design features. These features support practical goals in harsh service.

Operational outcomes for sampling lines include:

- Cleaner isolation at the sampling point

- Leak-tight closure reduces exposure risk during sampling and isolation.

- Lower contamination risk

- Pocketless flow design supports contamination control in sensitive circuits.

- Faster maintenance routines

- Field replacement supports shorter maintenance windows, with the body remaining in the line during diaphragm replacement.

What to look for in a valve for aggressive chemical service

Teams select valves for acid sampling lines under real constraints. Process chemistry, duty cycle, temperature, and access constraints shape outcomes.

Define the process media

Record chemical type, concentration, and temperature range. Use material safety datasheets to guide your selection process.

- Confirm operating conditions

Confirm pressure range and any pressure spikes. Confirm temperature swings and startup conditions. - Confirm compatibility requirements

Select body material, lining, and diaphragm material based on the media profile. Use the Saunders Type A catalogue as a technical reference. - Confirm installation constraints

Confirm end connections, pipe schedule, clearance, and access for maintenance. - Confirm duty cycle expectations

Record how often operators cycle the valve. High cycle points need stronger inspection planning. - Confirm control requirements

Confirm manual or actuated operation and position indication needs.

Material selection and corrosion resistance

Corrosion resistance depends on correct material selection. Stainless steel construction supports durability in harsh duties when alloy choice matches the media. Lining and diaphragm material selection also plays a central role in chemical service.

Treat chemical compatibility as a selection step, not a procurement afterthought. A mismatch between media and materials leads to premature failure and higher lifecycle cost.

Read more on workplace chemical hazard awareness and exposure control principles here: OSHA’s chemical hazards.

Leak prevention, safety, and compliance

Leak prevention supports safety and compliance in chemical handling zones. Leak-tight shut-off reduces chemical exposure risk for operators and reduces spill risk around sampling points. Saunders diaphragm valves are positioned for corrosive and abrasive duties, with product documentation emphasising leak-tight closure performance.

Maintenance planning and downtime control

Maintenance teams often judge valve value through downtime impact. Sampling lines require frequent use and frequent checks. Plan maintenance based on duty cycle and media severity.

A practical maintenance routine includes:

- Track sampling point cycle frequency

- Cycle tracking identifies high-wear points that need earlier inspection schedules.

- Inspect diaphragms during planned maintenance windows

- Planned inspections reduce emergency work and shorten recovery times.

- Stock spares for common sizes and duty profiles

- Spare diaphragms reduce downtime when wear appears during inspections.

- Train teams on isolation and replacement procedures

- Training reduces handling errors and supports safer work routines.

- Log failures with root cause notes

- Include chemical concentration, temperature excursions, and cleaning routines.

Specification checklist for engineers and procurement

Use this shortlist during selection and RFQ preparation:

- Process media profile with guidance from Material Safety Data Sheets

- Operating pressure profile, including peak events

- Valve size and connection standard

- Body material and lining requirements

- Diaphragm material requirements

- Operation type, manual or actuated

- Installation position and access requirements

- Maintenance intervals and spares plan

A clear checklist reduces procurement delays and reduces on site risks.

When to request technical support or an onsite valve audit

A site review supports risk reduction and cost control. Request support when you see:

- Recurring leaks or seal failures at sampling points

- Frequent downtime during diaphragm replacement

- Corrosion damage around valve bodies or connections

- Process changes and chemical changes

- Commissioning of new dosing or treatment lines

Contact DFC for technical support or onsite valve audit

Frequently asked questions

- What valve type suits acid sampling lines in power generation plants?

Diaphragm valves suit acid sampling lines because the diaphragm supports tight shut-off in corrosive service. Material selection must match the media. - Why do diaphragm valves suit aggressive chemical applications?

They separate the process media from the operating mechanism. This supports cleaner isolation and reduces exposure risk. - What defines leak-tight performance in chemical dosing systems?

Leak-tight performance relies on proven shut-off design, correct material selection, and disciplined installation and maintenance practices. - Where do Saunders diaphragm valves fit in power station water treatment?

Common placements include acid sampling lines, de-mineralised water systems, boiler feedwater treatment, cooling water chemical injection points, and WWTP duties. - How does stainless steel support durability in acid service?

Stainless steel supports corrosion resistance when alloy selection matches the chemical type, concentration, and operating temperature profile. - What maintenance steps reduce downtime on diaphragm valves?

Track cycling, inspect diaphragms during planned shutdowns, stock spare diaphragms, and train teams on safe replacement procedures. - What does an onsite valve audit cover?

A valve audit reviews application conditions, selection alignment, installation risks, maintenance access, spares readiness, and recurring failure causes. - How do diaphragm valves support safety and compliance in chemical handling areas?

Leak prevention reduces exposure risk and spill risk, supporting safer work routines and stronger environmental control. - Which specifications matter when selecting valves for boiler feedwater treatment?

Media profile, pressure and temperature limits, body and lining materials, diaphragm material, end connections, and operation method. Use MSDS information during selection.

When should a plant request technical support for acid sampling lines?

Request support after recurring leaks, frequent diaphragm wear, corrosion findings, chemical changes, or before commissioning new dosing and sampling lines.