Strengthening Sewage Infrastructure with High-Performance Vent-O-Mat Air Valves

Sewage and wastewater management systems play a critical role in public health and environmental safety. However, these systems are frequently challenged by air accumulation, pressure surges, and corrosion—factors that can lead to costly infrastructure failures and service disruptions.

To mitigate these risks, municipalities and utilities increasingly rely on advanced air valve technologies like the Vent-O-Mat RGX and RGXII series. These valves are engineered to address the unique demands of sewage systems by expelling corrosive gases, preventing blockages, and ensuring reliable system performance.

Common Issues in Sewage Pipelines

Sewage pipelines face unique challenges that require specialized air release technology:

1. Gas Accumulation & Pressure Buildup

- Gases such as hydrogen sulphide and methane corrode pipelines from within.

- Trapped air forms pockets, restricting flow and creating operational inefficiencies.

2. Structural Damage from Pressure Surge

- Sudden surges can rupture aging pipelines and cause severe leaks.

- High-pressure fluctuations accelerate wear and reduce the lifespan of critical components.

Proven Performance: Siza Water’s Experience with RGXII Valves

A compelling case study from Siza Water illustrates the real-world impact of deploying RGXII air valves. Prior to implementation, Siza faced challenges with air entrapment, frequent maintenance, and infrastructure strain. The RGXII valves resolved these issues with:

Self-cleaning mechanisms that handle solid waste without clogging.

Corrosion-resistant materials to withstand harsh sewage environments.

Superior sealing to prevent vacuum formation and extend infrastructure life.

According to Siza Water, the adoption of RGXII valves led to:

Reduced maintenance interventions and operational costs.

Improved pump efficiency and system reliability.

A noticeable drop in service disruptions, enhancing community trust.

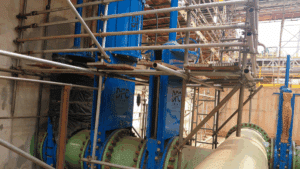

One notable project involved upgrading a sewage pump station plagued by inefficiencies. After integrating the RGXII valves, Siza reported better flow management, minimized downtime, and an overall boost in service delivery.

How Vent-O-Mat Air Valves Improve Sewage Systems

- RGX & RGXII Sewage Valves – Expel corrosive gases and prevent blockages.

- Solid Cylindrical Floats – Eliminate airlocks without clogging from solid waste.

- Surge Protection Mechanism – Reduces stress during peak flow periods.

Why Choose Vent-O-Mat RGX & RGXII Valves?

Solid Cylindrical Floats – Resist clogging and prevent airlocks in sludge-heavy systems.

Surge Protection – Minimizes pressure spikes during high inflow periods.

Energy Efficiency – Supports reduced power consumption and optimized pump performance.

By investing in Vent-O-Mat’s innovative solutions, municipalities can improve the sustainability and performance of their sewage networks—ensuring long-term cost savings and public health benefits.

Learn more: Vent-O-Mat Air Valve Technology

By integrating Vent-O-Mat’s high-performance air valves, municipalities can enhance sewage infrastructure, lower operational costs, and improve public health safety.

Need a reliable sewage air valve solution?

Contact Vent-O-Mat for expert assistance