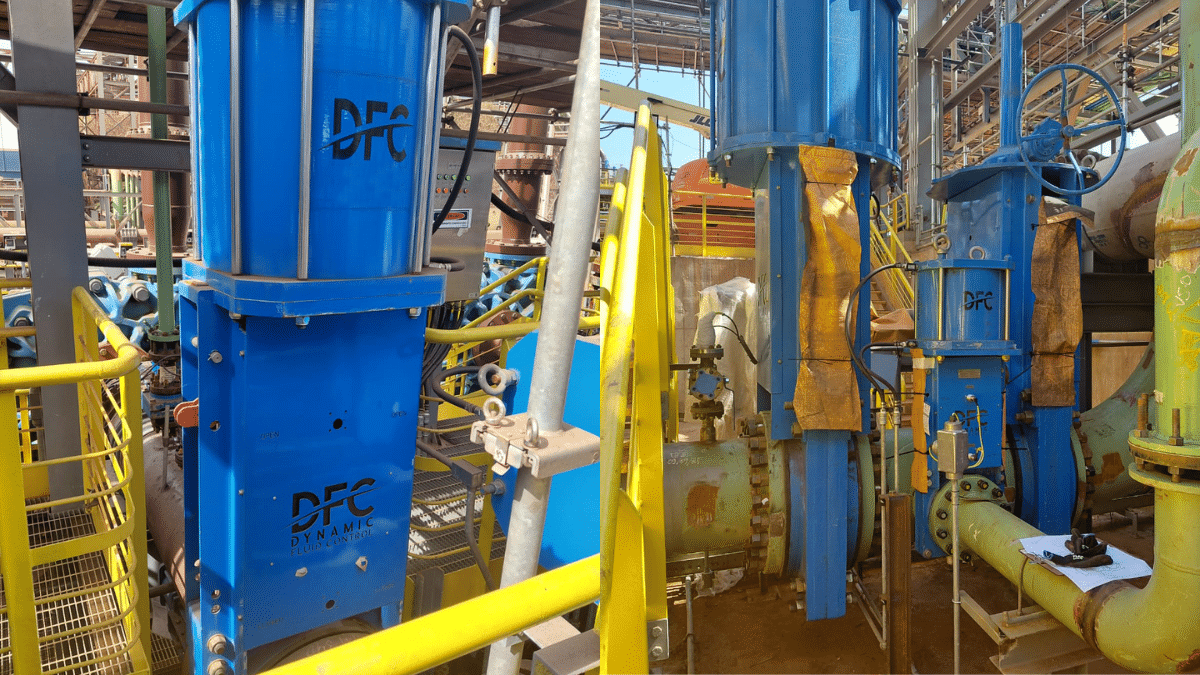

Selecting the right knife gate valve is critical for reliable isolation, reduced maintenance, and optimal performance in industrial systems. This guide explains how to choose an SKG knife gate valve that matches your media, pressure, size, and maintenance constraints, so you get leak-tight shut-off and long service life.

Understand Your Application

Clarify duty conditions before you select a model:

- Media type: slurry, water, effluent, pulp, chemicals, dry bulk solids

- Abrasiveness & corrosiveness: % solids, particle size, pH, chlorides

- Operating pressure & temperature: steady and transient peaks

- Flow conditions: continuous, intermittent, isolation duty, dead-end service

Quick tip: For abrasive slurry (e.g., tailings), prioritise bi-directional sealing, packingless sleeves, and field-replaceable components.

Key Selection Criteria

a) Valve Size

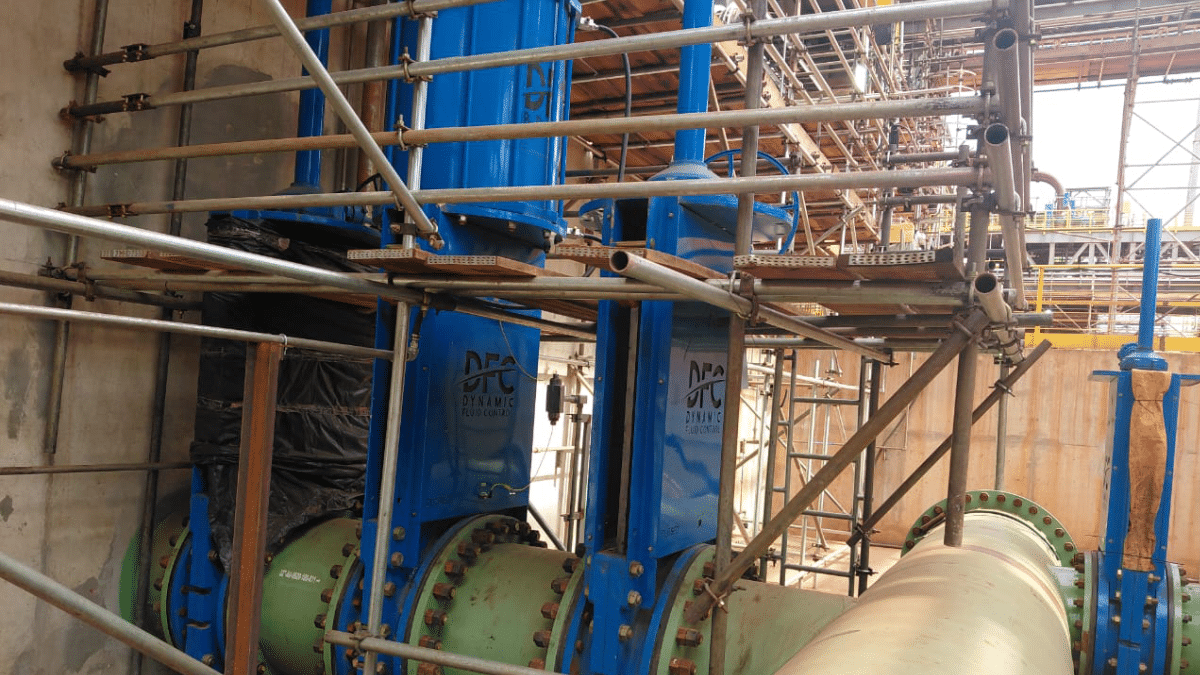

Match pipeline diameter from DN50 to DN1200. For large bores, check face-to-face, weight, actuator thrust, and lifting access.

b) Pressure Rating

- SKG (Standard): up to 10 bar

- SKG-HP (High Pressure): up to 51 bar for high-energy slurry and elevated surge risk

c) Materials of Construction

- Ductile iron – robust, cost-effective general duty

- Stainless steel (304/316) – corrosion resistance for effluent/chemical duty

- SAF2205 duplex – chloride-rich or highly erosive environments

d) Sealing & Design

- Bi-directional sealing – leak-tight in either flow direction

- Packingless sleeve design – minimises fugitive emissions and reduces maintenance

e) Actuation

- Manual (handwheel/gearbox)

- Pneumatic (fast, compact, simple control)

- Hydraulic (high thrust for large/HP valves)

- Electric (remote control, SCADA/PLC integration)

Environmental & Maintenance Factors

- Field replaceability: Replaceable sleeves and gates allow in-situ servicing, no valve removal, shorter outages.

- Space constraints: Wafer type bodies suit compact skids and retrofits.

- Maintenance access: Large-bore/HP valves may need extra clearance for actuators, lifting points, and lockout hardware.

Application-Based Recommendations

| Application | Recommended valve |

| Mining slurry lines | SKG Flanged or SKG-HP (for >10 bar or severe transients) |

| Wastewater treatment | SKG Wafer (space-saving) or SKG Flanged (robust tie-in) |

| High-pressure slurry | SKG-HP (up to 51 bar) |

| Large-diameter pipelines | SKG Large Bore |

| Chemical processing | Stainless steel SKG (SAF2205 where chlorides are high) |

Rules of thumb:

- Choose SKG-HP when PN > 10 bar, surges are likely, or solids are coarse/erosive.

- Choose Wafer when envelope is tight; Flanged where pipe loads and alignment matter.

- Choose stainless/duplex when corrosion or chlorides drive the design.

Safety & Compliance

- Provide lockout/tagout provisions for safe maintenance.

- Specify compliance to relevant ISO, SABS, and ANSI standards.

- Define actuator fail position (fail-open/fail-closed) for HAZOP scenarios.

FAQs

What makes SKG valves suitable for abrasive media?

Heavy-duty elastomer sleeves and corrosion-resistant gates protect seating surfaces, delivering reliable bi-directional shut-off in high-solids service.

How do field-replaceable sleeves reduce downtime?

They allow quick on-site sleeve changes without removing the valve from the pipeline, reducing lifting, alignment, and outage time.

Wafer or flanged—how do I decide?

Use wafer when space is tight and line loads are small; use flanged for structural rigidity and easier alignment on larger bores.

Resources

- Download: SKG Catalogue (PDF)

- Explore products: SKG range

- Related DFC solutions:

- RF Valves – pinch valves for slurry throttling

- Vent-O-Mat – air release & surge protection