Chemical handling systems in power stations rely on controlled isolation at dosing points, sampling points, and treatment lines. When shut-off performance drops, leaks increase exposure risk, trigger corrosion damage, and create avoidable downtime. Saunders offer leak-tight valves shut-off options for corrosive and abrasive duties, supported by material and lining choices for harsh media.

What “leak-tight” should mean in your valve selection process

Teams often describe a requirement as “leak-proof,” but procurement and engineering teams need something measurable. In valve standards, two ideas matter most: closure tightness and external leakage. ISO 5208 covers tests used to verify valve closure tightness, while ISO 15848-1 focuses on evaluating external leakage from valve stem seals and body joints for valves used with hazardous fluids.

A practical way to apply this on site:

- Define the duty: media, concentration, temperature, pressure.

- Define the risk: operator exposure and spill consequences.

- Define the test expectations: closure tightness and external leakage controls.

- Define the maintenance plan: how you will keep leak-tight performance over time.

Why diaphragm valves suit chemical handling better than many alternatives

Chemical dosing and sampling often involve aggressive media and frequent cycling. Diaphragm valve design separates the operating mechanism from the process media through the diaphragm, which supports cleaner isolation in chemical service. This also supports routine maintenance planning because the diaphragm is a defined wear component that teams can inspect and replace on schedule.

A Type vs KB Type: both leak-tight valves by design, built for different duties

A common misunderstanding is that only one valve type provides leak-tight performance. On DFC product pages, both A Type and KB Type are described as leak tight by design. The selection decision depends on body design, flow requirements, and site constraints, not on leak-tight capability alone.

When to choose Saunders A Type

Use Saunders pocketless A Type diaphragm valves when your priority is contamination control, straightforward maintenance, and flexible installation.

Pocketless design supports contamination-free performance and smooth flow characteristics.

- Usable in any position and self-draining at a horizontal plane 15 degree angle, which supports practical installation.

- Leak tight by design, with immediate open and close indication.

- Three-part construction supports diaphragm replacement with the body remaining in the pipeline, which supports faster maintenance windows.

Download Saunders A Type Catalogue

When to choose Saunders KB Type

Use Saunders straight-through KB Type diaphragm valves when you want high flow, low pressure drop, and practical handling where solids may be present.

- Straight-through body supports high flow and low pressure drop.

- Leak tight by design, with flexible closure when solids are present.

- Only the body and diaphragm contact the media, which supports chemical service isolation requirements.

- Sealed bonnet design supports improved resistance to corrosion and abrasion, with lining and diaphragm options available.

Download Saunders KB Type Catalogue

A fast decision guide for power station teams

Choose A Type if:

- You want contamination control and pocketless performance.

- You need flexible installation and self-draining behaviour.

- You want simple maintenance with fast diaphragm replacement in line.

Choose KB Type if:

- You need high flow and low pressure drop.

- You have solids present or risk of solids in the media.

- You need straight-through geometry for layout or process reasons.

If you need deeper technical detail for internal review, use the Saunders Type A catalogue PDF and the Saunders KB catalogue PDF.

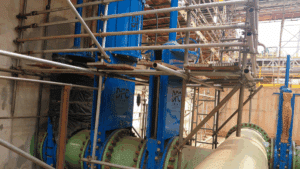

Where these valves typically sit in chemical handling systems

Chemical handling spans multiple plant areas. Selection works best when teams map each valve to a duty profile, rather than using one valve type for everything.

Typical placement areas include:

- Chemical dosing lines for conditioning and pH control.

- Sampling points on treatment and monitoring circuits.

- De-mineralised water systems where purity and contamination control matter.

- Boiler feedwater treatment points where chemical compatibility matters.

- Cooling water chemical injection points where stable dosing matters.

Procurement checklist for leak-tight chemical service

Use this checklist to reduce selection errors and improve lifecycle value.

Media profile pack

- Chemical names, concentrations, and temperature ranges.

- Cleaning and flushing chemicals.

Operating envelope

- Normal pressure and peak events.

- Temperature swings during start-up and shutdown.

Materials and compatibility

- Body material and lining selection.

- Diaphragm material selection matched to media and duty cycle.

Installation and access

- Connection standards and installation geometry.

- Access for inspection and diaphragm replacement.

Operations and safety

- Manual or actuated operation requirements.

- Position indication needs for isolation procedures.

- Procedure alignment to chemical hazard controls.

Maintenance planning: how to keep leak-tight performance over time

Leak-tight performance depends on selection and upkeep. For diaphragm valves, maintenance planning should treat diaphragms as controlled wear items.

- Track cycle counts at sampling and dosing points.

- Inspect diaphragms during planned shutdown windows.

- Stock spare diaphragms for critical sizes and locations.

- Keep a failure log with media details and temperature events.

This approach reduces emergency callouts and supports predictable shutdown planning.

When to engage technical support

Engage technical support when risk increases, duty changes, or failure repeats.

- Media changes in dosing or treatment.

- Recurring diaphragm wear at one point.

- Recurring leaks during isolation or sampling.

- Corrosion findings around valve bodies or joints.

- Commissioning of new dosing or sampling skids.

Contact us for technical support and enquiries using the contact page.

Frequently asked questions

- Is the Saunders A Type leak tight?

Yes. The A Type page lists leak tight by design. - Is the Saunders KB Type leak tight as well?

Yes. The KB Type page lists leak tight by design. - What drives selection between A Type and KB Type?

Duty and geometry. A Type suits pocketless weir-style applications focused on contamination control. KB Type suits straight-through flow where high flow and low pressure drop matter. - Which standards help define leak-tight requirements?

ISO 5208 helps frame closure tightness verification. ISO 15848-1 helps frame external leakage evaluation for valves used with hazardous fluids.